- HOME

- News

- Corporate Information

- Investor Relations

- Products Information

- Transportation Systems

- Transportation Systems Products

- Propulsion inverters

- Auxiliary Power Supply

- Traction motors

- Driving gear units

- Pantograph

- The total train communication system

- The passenger information display system

- Twin disk couplings

- Door operating equipment

- High speed circuit breakers・Unit Switch

- Railway Power Storage System

- E3 Solution System

- Industrial Systems

- Testing System for Automobiles

- Testing System for Automobiles

- Dynamo (dynamometer)

- Mechanical Systems

- Control and Measurement Operations

- Battery Simulator

- Power Generation and Social Infrastructure System

- Emergency Generators

- Continuous-Use Generators

- Generating Equipment for Distributed Power Source

- Water Supply and Sewage Equipment Systems

- Production and Processing Equipment Systems

- Toyo Network System

- Printing

- Tire and Rubber

- Films and Plastics

- Paper Manufacturing

- Metal Processing

- Automotive Electrical Equipment

- Lineup

- Information Equipment Systems

- Station Operating equipment Systems

- Commuter pass vending machine / Composite ticket vending machine

- Mobile device for the conductor

- Compact vending machine

- Decision Engines

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring Solution

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- IORemoter Terminal for

Remote Monitoring and Control System - Electricity Visualization Solution

- Wireless Current Sensor μTURTLE-I

- Wireless Electricity Sensor μTURTLE-P

- Wireless Analog Sensor μTURTLE-A

- Wireless Pulse Sensor μTURTLE-PL

- Receiving Unit

μTURTLE-R、RL、RW

- ESG / CSR

- Contact Us

- HOME

- Products Information

- Industrial Systems

- Automotive Electrical Equipment

Industrial Systems

Automotive Electrical Equipment

Toyo Denki’s power electronics technology is contributing to advances in high-efficiency permanent magnet-type motors and control technology, aiding the market growth of electric and hybrid electric vehicles.

Solutions

Supporting diverse vehicles

Solutions for the electrification of diverse vehicles ranging from passenger cars, trucks, and buses to compact industrial vehicles and large construction machinery

Customizable to specifications of customer

Customizable to the requirements of the customer and built around Toyo Denki’s core technologies for motors, inverters, and communications technology. Negotiable delivery to meet tight deadlines

Small lots for testing and research, up to commercial mass production

Support small lots for testing and research, up to commercial mass production.

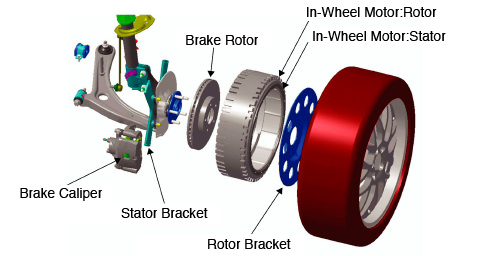

Compact, lightweight, low-noise equipment

Maximum motor torque density: 20 Nm/kg

Maximum torque ratio cogging torque: 0.1% or less

(actual measured values from outer rotor type direct drive motor)

High efficiency and performance

Leveraging variable-speed motor drive technology developed throughout the Company’s history to supply high-efficiency, high-performance equipment designed and manufactured for vehicles.

EV/HEV Drive System

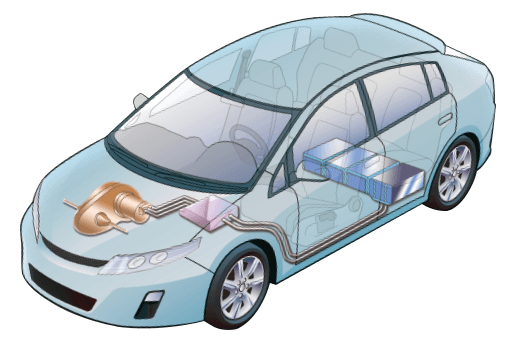

For passenger vehicle

Low-loss, high-efficiency drive motor to suppress system heat generation. The temperature rise is kept to a minimum under high load conditions, making it possible to keep the cooling system compact and lightweight and also providing for a reliable, long-life drive system.

Motor for EV

Inverter for EV

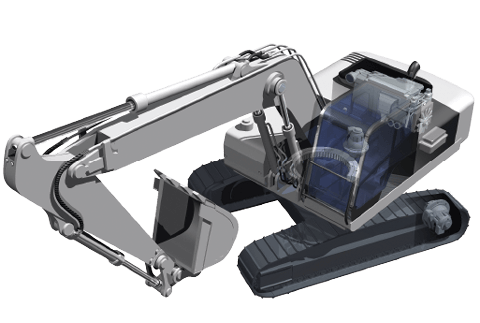

For construction machinery

Robust structure that is resilient to vibration and impact characteristic of tough construction machinery environment. The system uses regenerative operation to store power from the energy generated under high frequency use.

For bus

A power bus system using a series hybrid that integrates the engine with the power generating motor, which makes it possible for a more compact layout that requires less space on the vehicle side.

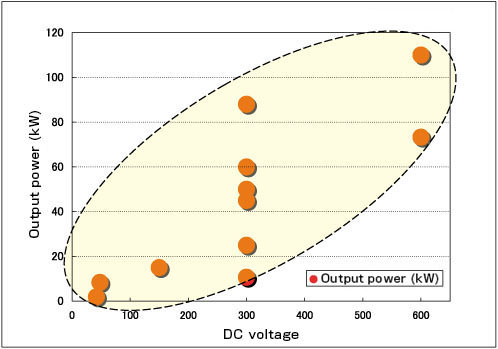

Performance on an individual output basis

Established track record in development and production combining an output range of 0.5kW to 110kW with a direct current drive voltage range of 40V to 600V.

- Transportation Systems

- Industrial Systems

- Information Equipment Systems

- Station Operating equipment Systems

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- Remote Monitoring and Control System

- Electricity Visualization

- Wireless Current Sensor

- Wireless Electricity Sensor

- Wireless Analog Sensor

- Wireless Pulse Sensor

- Receiving Unit

PAGE TOP